-

Liutang Town Industrial Park, Liucheng County, Guangxi

Your Trusted Phosphate Partner

Serving 500+ global food brands with certified quality for product innovation and compliance

Success Stories: Goway Phosphates Innovating Industries

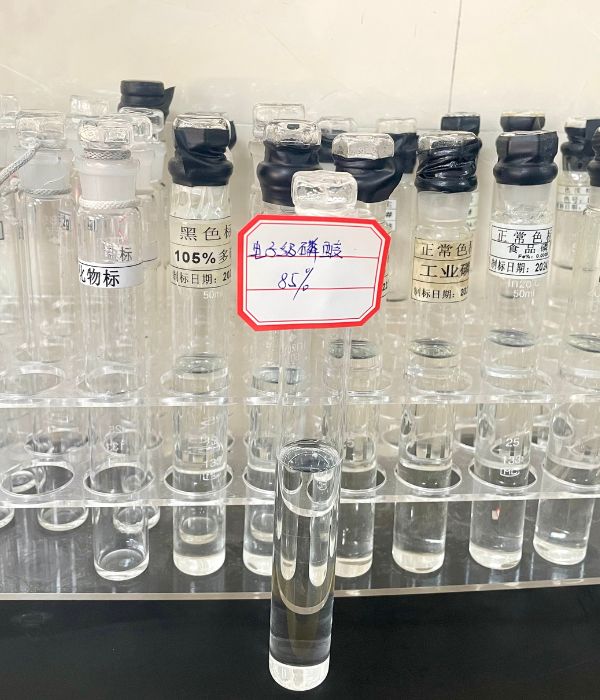

Beverage Giant Achieves Perfect pH Consistency with Food-Grade Phosphoric Acid

Client: A Top 3 Global Cola Manufacturer

Challenge: Inconsistent tartness and acidity in Asian markets

Solution:Supplied 85% food-grade phosphoric acid with ultra-low impurities (< 3 ppm heavy metals)

Provided pH stabilization consulting to adjust regional water variations

Results:

✔ 15% improvement in flavor consistency across batches

✔ Faster production cycles due to a reliable acid supply

✔ Expanded market share in India and Southeast Asia

Frozen Seafood Exporter Reduces Product Waste by 18%

Client: Vietnam’s #2 Shrimp Processor

Challenge: High thawing drip loss (20%) is hurting profitability

Solution:

Custom STPP blend optimized for moisture retention

Halal-certified production for Middle East compliance

Results:

✔ 18% less product waste post-freezing

✔ Extended shelf life by 25 days

✔ Won new contracts with Dubai supermarkets

Plant-Based Meat Startup Mimics Real Meat Texture

Client: European Vegan Food Tech Company

Challenge: Poor chewiness in pea-protein burgers

Solution:Developed a low-sodium phosphate blend for fiber binding

Clean-label compliant (no synthetic additives)

Results:

✔ 90% closer texture to real beef in blind tests

✔ 30% faster production vs. competitor additives

✔ Featured in “Top 10 Food Tech Innovations 2023”

Dairy Producer Solves Yogurt Shelf-Life Crisis

Client: Chinese National Yogurt Brand

Challenge: Spoilage during summer distribution

Solution:

MKP (Monopotassium Phosphate) stabilizer system

Microbial safety testing for tropical climates

Results:

✔ Shelf life extended from 14 to 28 days

✔ Zero quality complaints during heatwaves

✔ Saved ¥2M/year in reduced returns

What Our Client’s Say

Goway's food-grade phosphoric acid ensures perfect pH consistency across our 12 plants. Their technical support helped reduce quality adjustments by 15%.

After implementing Goway's STPP solution, we reduced moisture loss in our frozen shrimp from 18% to just 5%. Their Halal certification support helped us secure contracts with Middle Eastern buyers worth $2M annually.

The custom phosphate blend developed by Goway's chemists gave our pea-protein burgers the fibrous texture we'd been missing. Their clean-label approach aligned perfectly with our brand values.

Goway's MKP stabilizer system extended our probiotic yogurt shelf life by 100% during summer months. Their microbial safety protocols exceeded our internal standards.

Goway's USP-grade phosphoric acid met our strict particulate requirements and accelerated our FDA approval process. Their documentation support saved us 60 days of regulatory review time.

The SAPP leavening agent from Goway provides perfect rise consistency in our frozen croissants. Their technical advice on usage levels helped us reduce ingredient costs by 12%.

Latest from Blog

We hope that through this latest blog content, you will be able to gain valuable insights that will help you make better decisions and grow in your respective fields.

Sodium Hexametaphosphate: What You Need to Know About This Food Additive

Sodium hexametaphosphate is a common food ingredient. You have likely seen its name on the labels of many…

Tetrasodium Pyrophosphate (TSPP): Your Guide to This Food Additive, Its Uses, and Side Effects

Tetrasodium pyrophosphate, or TSPP, is a common food additive. You have probably eaten this ingredient in chicken nuggets,…

Opening the Scientific Research of Noodles: Exactly How Salt Tripolyphosphate (STPP), a Phosphate Salt Additive, Shapes Your Favorite Food

Pastas , a worldwide staple beloved throughout societies, are more than simply flour and water. Behind the scenes, phosphate salts like salt…